The Internet of Things (IoT) is at the heart of rapid development in all sections of the global economy. Supply chain management and the warehousing industry are no exceptions to this growing trend. The proliferation of IoT has already started changing the picture for the better. Still, adoption of this technology is moving at snail’s pace.

Let’s see the role IoT is playing in warehouse management today and what the future of this technology looks like, says Jaykishan Panchal, a content marketing strategist at MoveoApps.

What is IoT?

IoT, or Internet of Things, refers to a system of connected devices such as home and office appliances, vehicles, and other equipment through the internet. These devices can exchange data with each other with human-to-human or human-to-computer interaction.

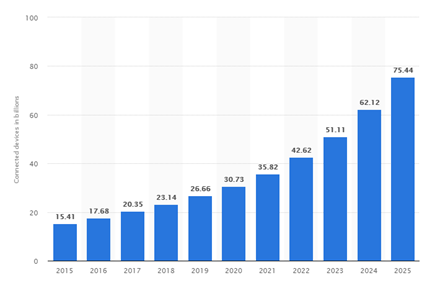

Source : Statista

According to Statista, the installed base of IoT devices is forecast to grow to almost 31 billion worldwide by 2020, and it will be 75 billion by 2025. That’s a staggering number of connected devices.

But, how will this IoT-based connectivity benefit warehouse management?

Benefits of using IoT

The inherent nature of a traditional warehouse management system makes it difficult to improve efficiency. Plus, cut-throat competition and volatile global economy are eating into the profit margins in the warehousing industry. This is where IoT-based smart warehouses come in.

- Reduced costs

The primary benefit of having IoT-based smart warehouses will be reduced overall handling costs. Everything, from managing inventory to maintenance, will be planned down to a T.

As a result, IoT will ensure optimal utilisation of labor, utilities, and the storage space. In other words, a smart warehouse will waste no resources, resulting in increased profits and reduced management costs.

- Next generation real-time tracking

It is the next generation of real-time tracking. With IoT, you can track materials, equipment, and products more quickly and accurately as they move through the supply chain.

Connected devices and sensors can help monitor the quantity and quality of goods second by second. This ability can transform the perishable food industry, which suffers heavy losses due to spoilage as sensors can help monitor the temperature as well as the location of the cargo.

- Seamless workflow

IoT will allow you to monitor the flow of incoming and outgoing supply chains through the warehouse. Workers will be able to find the exact location of cargo within the warehouse with real-time location service.

You can use robots to retrieve specific articles without delay. You can also use the data collected by IoT devices to determine the best layout and configuration of the warehouse. Thus, you will be able to maintain a seamless workflow at its fullest efficiency.

- Increased scalability

As you can optimise every square inch of your storage space with IoT, scaling it according to your needs is going to be relatively easy. With the help of past data, you can calculate the time, space, infrastructure, and investment required for the scale up.

You can also integrate one IoT-based warehouse with the other as your network grows. You will be able to bring the new facilities on board promptly, resulting in quick turnaround time. It provides you with competitive advantage over your rivals.

Jaykishan Panchal

- Improves forecasting accuracy

Supply chain management, particularly for the e-commerce industry, experiences seasonal ups and downs. For example, you have to handle more traffic during the holiday season.

IoT-based warehouses can collect and process inventory data to forecast potential increase or decrease in workload. It can send appropriate alerts to warehouse managers, providing them with ample time to prepare for the changing demand. In future, smart warehouses will be like self-sustaining ecosystems that can adjust storage space as per market fluctuations.

Companies using IoT warehouse systems

Many 3PL companies and even e-commerce giants are using a variety of IoT technologies for efficient real-time warehouse inventory management.

- Ocado

Ocado, a British online-only supermarket is already using automated warehouses. Its most advanced warehouse in Andover can process around 3.5 million items or 65,000 orders every week. It comprises more than one thousand robots that look like a washing machine.

[embedded content]

An AI-based algorithm stores the items by demand forecast with frequently ordered items getting placed on the top and the ones rarely bought at the bottom. The entire system looks like a hive-grid machine. Ocado has created a scalable model where you can add more robots and crates to suit your warehousing targets.

- Amazon

Global e-commerce giant Amazon has also made significant strides in warehouse management automation. With 493 warehouses covering around 180 square million feet globally, Amazon has roped in 100,000 robots so far.

[embedded content]

They also acquired Kiva Robots, which produced the first-ever warehouse robots for the company in 2012 for $775 million (€677.2 million). It is now called Amazon Robotics and continues to fulfill its thirst for inventory management automation. The robots can carry up to 750 pounds of load while navigating along pre-programmed 90-degree-angle paths.

- Alibaba

Just like Amazon, the Chinese e-commerce titan Alibaba has also invested heavily in warehouse automation. The company is already using AGVs and a host of other technologies to increase warehouse productivity. Recently, Alibaba announced about investing more than $15 billion (€13.1 billion) to set up a smart logistics network aimed at improving delivery reach and efficiency.

[embedded content]

Cainiao, Alibaba’s logistics affiliate, has built a “Future Park” logistics complex in the city of Wuxi, near Shanghai. It houses a smart warehouse, offices, and shops. It uses technologies such as AI, cutting-edge computing, more than 500 AGVs, and Long Range (LoRa) IoT.

The author of this blog is Jaykishan Panchal, a content marketing strategist at MoveoApps

About the author

Jaykishan Panchal is a content marketing strategist at MoveoApps, a mobile app development company. He enjoys writing about technology, marketing and industry trends, and is a tech enthusiast.

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow

Leave a Reply