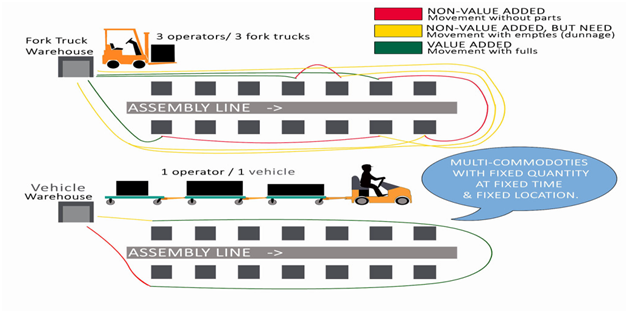

The concept of Fork Truck Free (FTF) is not mentioned in the graphic above, yet it is addressed in each element. Let’s look more closely.

Integrated supply chain management utilising FTF initiatives are indeed revolutionising the way products are designed, produced, and delivered while maximising efficiencies and savings with a connected supply chain. Steps walked throughout a plant or repetitive fork truck runs back and forth are eliminated with mother-daughter carts.

Mother-daughter carts are an industrial cart system consisting of one large mother cart and two or more, smaller daughter carts. The daughter carts are designed to fit within the mother cart’s framework. Once inside, the daughter carts are locked into the mother cart. The mother cart and daughter carts are then able to be tugged as one. Daughter carts are often different types of carts.

One mother cart can be designed to carry a static cart as a daughter cart and a rotation cart as a daughter cart. The Mother Daughter Cart System is a very flexible, effective cart system. It facilitates an integrated supply chain by bringing products to the line as needed, increasing efficiencies.

Prescriptive analytics are also part of an FTF initiative. By maximising outcomes based on predictive analytics ensures optimal uptime and sustained performance. Carts are delivering a high-level material flow, bringing the right product to the line at the correct time.

Real-time visibility allows carts to be monitored and reduce (even eliminate) fork truck utilisation. Insightful decision-making becomes possible in the FTF space because all raw materials, finished goods, are delivered to a manufacturing cell or shipping dock precisely as needed. Zero wait-time is accomplished which eliminates downtime, improves labor efficiency, and ensures maximum productivity.

FTF initiatives are an extension of IIoT

Because IIoT (Industrial Internet of Things) is an extension of both the engineer and IT, the ability to properly sequence production becomes an automated exercise. IIoT represents the way in which FTF initiatives capture the convergence of the digital and physical worlds—including information technology and operations technology.

This transformation of the supply chain increasingly shifts from linear, sequential supply chain operations to an interconnected, open system of supply operations allowing manufacturers to fully realise the digital supply network.

This is not a panacea, however when starting with the FTF initiatives, manufacturers are better prepared to unlock several capabilities including horizontal integration through the myriad operational systems that power the organisation; vertical integration through connected manufacturing systems; and end-to-end, holistic integration through the entire value chain.

A new manufacturing line can produce one product and up to 25 variants, with a 10% increase in productivity and a 30% decrease in inventory by using IIoT and Industry 4.0 technologies.

While productivity, throughput, and operational efficiency are an obvious outcome of FTF initiative, the prognosis of IIoT to transform manufacturing operations far exceed the initial benefits of productivity. Flexibility, quality, and speed are natural consequences achieved as organisations use FTF initiatives to become best-practice manufacturers.

The authors of the blog are Ed Brown and Ryan Brown

Author profiles

The engineering foundation of migrating from a fork truck material flow to Fork Truck Free operational efficiencies are represented by Topper Industrial founder Ed Brown and son Ryan Brown, president of the Wisconsin-based industrial cart FTF revolution.

Ed Brown is considered the father of the North American fork truck free (FTF) movement. In 1994, Brown opened the operations of Topper Industrial, a leading manufacturer of various material handling equipment in Sturtevant, Wisconsin.

The company proves highly innovative in finding solutions to the needs of an ever-changing industrial work environment. Brown is an inventor of many industrial cart and conveyors solutions. He holds several patents through his years running Topper.

Most of the patents relate to ergonomics and safety primarily in the material handling sector. These patented products are extensive and include mechanical advancements on Topper’s tow bar, couple system and cart handle. Brown also holds a patent on tilt carts, and many other Topper products are patent pending.

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow

Leave a Reply