Moxa provides a full spectrum of products for industrial networking, computing, and automation, and maintains a distribution and service network that reaches customers in more than 70 countries. Its products have connected over 50 million devices worldwide in a wide range of applications, including factory automation, smart rail, smart grid, intelligent transportation, oil & gas, marine, and mining. Here, Robin Duke-Woolley (RDW), CEO of IoT industry analyst firm Beecham Research, interviews Stefan Palm (SP), business development manager – Embedded Computing at Moxa.

RDW: The convergence between operational technology (OT) and information technology (IT) has meant a significant change for industrial environments. What is Moxa’s approach to bridge the gap between these two worlds?

SP: Actually, it is a change for the people in the IT environment, too, because both worlds are moving closer together – and OT as well as IT people have to leave their comfort zones as they are being confronted with the reality that has developed outside of their scope.

Stefan Palm

Moxa

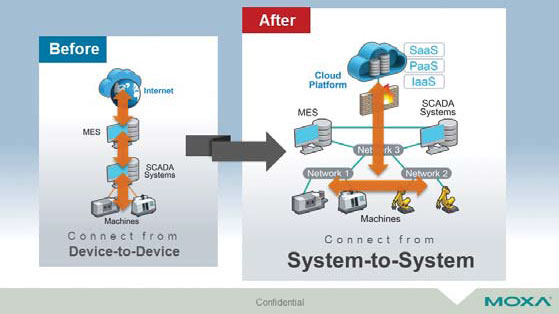

For both kinds of experts it can be compared with starting to learn a new foreign language. OT people are used to Fieldbus protocols that are often based on serial communication principles. They have developed efficient ways to pass the information gathered by sensors on to the management level, for example via SCADA systems. Yet, they are not very familiar with systems in an enterprise environment that use TCP/IP based protocols to efficiently transfer information over the Internet, store it in datacenters and manage the big data in a way that enables them to retrieve information through the visibility of a much bigger database.

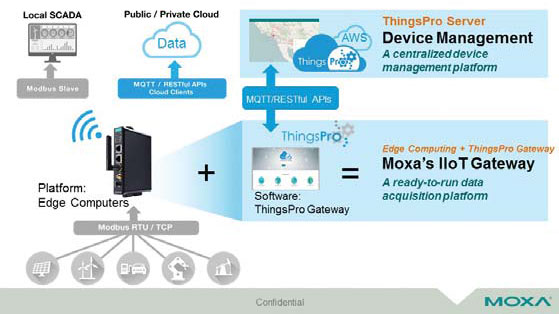

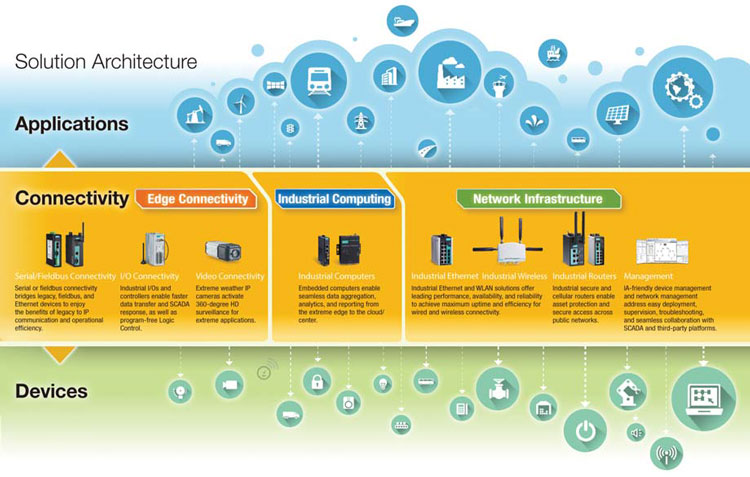

This is the expertise and domain of the IT people who are usually unaware how the data from a single sensor finds its way into the enterprise world. As an expert in acquiring data in the field, converting it from one protocol to another and then transferring it securely and reliably, Moxa bridges the gap and makes the data available in a format that IT people are used to and can deal with.

The same happens in the other direction when it comes to giving commands towards devices in the field as a result of complex analyses done in data centers. These commands, of course, also need to be converted into a format OT people can understand and manage.

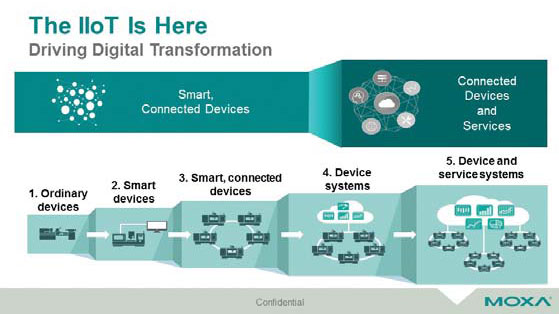

Moxa´s core business is to build the foundation for successful IIoT and Industry 4.0 implementations by connecting even legacy devices and making the data available and understandable for people in both worlds.

RDW: In the industrial IoT space, what do you see as the main challenges and how should they be addressed?

SP: Industrial IoT (IIoT) is currently facing three major challenges:

- Connecting devices in the field and making the data available and usable in private and public clouds to be utilised by OT and/or IT systems

- Making sure the acquired and transferred data is protected and will be available for the intended user only

- Assuring that the data transfer happens in a deterministic way and in real time to enable full control even in critical situations

To master challenge 1, devices are necessary that can forward the data acquired in the field on sensor level and even translate them in a way that they can be understood by the big number-crunchers up in the cloud – which will then eventually come back with some meaningful actions to optimize the processes monitored by the sensors. The major obstacle is the lack of standards that can be applied to streamline the access methods. Currently, this point is being addressed, and the effort is progressing as we speak. There are promising candidates like MQTT, Restful API or OPC-UA that have the potential and are widely accepted by the industry. However, this is work in progress and we may see more in the future.

Challenge 2 is the wide field of cyber security and the ability to protect the environment from attacks, to avoid unauthorized access to machines, the production environment or even the complete plant, respectively. IEC 62443 is a widely accepted guideline that may guide you in achieving this. Yet, this requires the support of any member in the communication chain down to device level. However, this is just a start and needs further development in order to deal with the specific requirements of different industry segments which may need variation.

Mastering challenge 3 is extremely important to ensure data integrity. The technology that addresses this issue is called TSN (Time Sensitive Networking). TSN is a set of standards under development by the Time-Sensitive Networking task group of the IEEE 802.1 working group. The different TSN standards can be grouped into three basic key component categories that are required for a complete real-time communication solution:

- Time synchronisation

- Scheduling and traffic shaping

- Selection of communication paths, reservation and fault-tolerance

TSN will play an important role in the future, but it still needs to be widely adapted in order to become effective. This is work in progress, too.

RDW: Can you provide an overview of your activities in the smart rail and intelligent transportation segments?

SP: Smart rail and intelligent transportation are additional sectors where Moxa is quite active. We are actively contributing to the IEC TC9 WG43 standard to define the next generation of TCN (Train Communication Network). The latest achievement is the release of the IEC 61375 that specifies the onboard communication and in particular the Train Control and Management System (TCMS).

In cooperation with leading train manufactures like Alstom and Bombardier, Moxa was able prove the interoperability of our devices. This makes us one of the leading manufacturers for network devices on board of trains. And we are still actively driving the standards forward. Another initiative is the contribution to an effort called Safe4Rail (https://safe4rail.eu) under the umbrella of Shift2Rail (https://shift2rail.org/) which is funded by the EU.

Safe4Rail provides the baseline for a fundamentally simplified embedded computing and networked TCMS platform for the modular integration and certification of all safety, time and mission critical train functions, including distributed hard real time controls, safety signals and functions up to SIL4. The results are demonstrated with a SIL4 brake-by-wire system safety concept. Ultimately, the project provides recommendations for the standardization and certification of next generation TCMS embedded platforms.

RDW: Considering Moxa’s focus on providing industrial networking solutions for the critical infrastructure sectors, how are you helping companies overcome the challenges they are facing around security?

SP: Moxa has already adopted the IEC 62443 standard on device level in a variety of our devices in order to provide the feature set that is required to satisfy even higher levels of requirements to secure the system and even the environment. The next step is the full integration into Moxa’s MxView real time network management software toolset in order to allow customers to assess their current situation and to suggest the necessary steps to achieve the desired security level. Moreover, Moxa is participating in different industrial consortia to keep the discussion going and to shape the requirements, so they will eventually become industry standards – and, of course, to ensure constant security improvements to make our world a bit safer every day.

RDW: Transportation and factory automation are often mentioned as industries expected to lead the adoption of 5G technologies. What is your expectations of 5G and its potential impact in these markets?

SP: 5G will change the communication infrastructure significantly as, for first time, a wireless cellular technology will offer a performance as high as 20 gigabits per second which is up to ten times higher than the current 4G networks. This is a considerable performance boost that will allow the deployment of cellular networks in places where the bandwidth requirements cannot be fulfilled today.

There will be clear savings, too, especially regarding cabling as this will be no longer required. Moreover, installation and maintenance will become much easier and less costly. So, traditional wired Ethernet or Wi-Fi networks will migrate to wireless cellular technologies based on 5G. It will also enable real time applications based on TSN over telephone infrastructures, so we are expecting a shift towards this kind of network setups.

Leave a Reply